| TECHNOLOGICAL CARD |

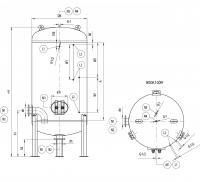

CONNECTORS

N1: water inlet, N2: water outlet, N3: vent valve connection socket, N4: compressed air inlet, L1: connector for manometer, L2: connector for water gauge, M1: revisory manhole

BASIC HYDROPHORE VESSEL PARAMETERS

| Type |

Nominal diameter DN [mm] |

Capacity V [Litr] |

Total height H [mm] |

Jackets height h [mm] |

Height from the base to connector arbor h1 [mm] |

Height from the base to connector rebate h2 [mm] |

Connection socket diameter dn [mm] |

Distance between water-level gauge connectors |

Mass - work [kg] |

||

| W1 [mm] | W2 [mm] | A | B | ||||||||

| HP 1 | 800 | 800 | 2138 | 1250 | 896 | 300 | 80 | 1130 | - | 216 | 264 |

| HP 2 | 900 | 1000 | 2188 | 1250 | 921 | 300 | 80 | 1130 | - | 249 | 302 |

| HP 3 | 1000 | 1300 | 2292 | 1250 | 996 | 350 | 100 | 1130 | - | 396 | 404 |

| HP 4 | 1000 | 1500 | 2542 | 1500 | 996 | 350 | 100 | 1380 | - | 434 | 440 |

| HP 5 | 1200 | 2000 | 2492 | 1350 | 1046 | 350 | 100 | 1130 | - | 510 | 631 |

| HP 6 | 1200 | 2500 | 2892 | 1750 | 1046 | 350 | 100 | 720 | 720 | 583 | 736 |

| HP 7 | 1400 | 3200 | 2842 | 1500 | 1196 | 450 | 150 | 700 | 700 | 660 | 877 |

| HP 8 | 1400 | 3900 | 3342 | 2000 | 1196 | 450 | 150 | 900 | 900 | 766 | 978 |

| HP 9 | 1600 | 6800 | 4192 | 2750 | 1244 | 450 | 150 | 1000 | 1000 | 1090 | 1361 |

| HP 10 | 1800 | 6200 | 3292 | 1750 | 1294 | 450 | 150 | 840 | 840 | 976 | 1175 |

|

The way of type marking: eg. Hydrophore HP 3 A - vessel V=1307 litres, work A, PS=6 bar, TS=20°C . For the given parameters the tolerance shall be taken according to existing rules. |

|||||||||||

USE

Hydrophore vessels are used for keeping (stabilizing) the required water pressure in water-pipe network and for protecting siutable water reserve (water storage). Hydrophore vessels are one of the basic elements of hydrophore plants or water purification plants.

Vertical hydrophore vessels work A are used in cold water systems at max. permissible pressure PS=6bar and max permissible temperature TS=20°C.

Vertical hydrophore vessels work B are used in cold water systems at max. permissible pressure PS=10bar and max permissible temperature TS=20°C.

HYDROPHORE VESSEL CONSTRUCTION

All the basic hydrophore vessel elements (mantle, ellipsoidal bottom heads, manholes, connectors, etc.) are made of certified carbon steel. The permissible pressure PS can be exceeded while exploiting the vessel. The consrtuction allows full internal revision through oval or eliptic revisory manhole.

Hydrophore vessel is protected against to corrosion: internally - polyester resins with PZH certification for contact with drinking water, externally - universal primer paint. Manufacturer allows using other internal varnish sets (eg. epoxy resins) and works with external surface painting (eg. set of polyurethan paints) – for clients' special wishes.

Manufacturer can also offer devices with other anticorrosion protections eg. by:

- hot galvanizing, two-sided

- spray galvanizing, one or two-sided

- ebonit lining (rubbering)

We also offer hydrophore vessels made of austenitic steel.

The manufacturer allows any constructional changes of the vessel in the range of connector sockets' diameters and placing.

SAMPLE CONNECTION SCHEME OF A HYDROPHORE

phocagallery view=category|categoryid=29|imageid=102}