| TECHNOLOGICAL CARD |

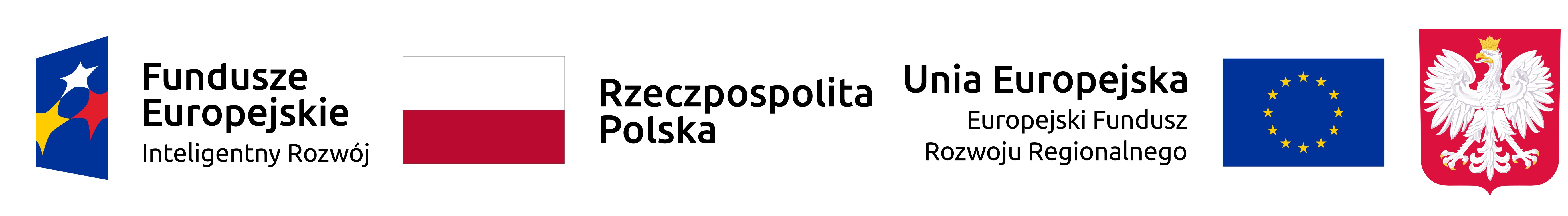

OPIS KRÓĆCÓW

N1: wlot powietrza, N2: wylot powietrza, N3: spust, N4: pod zawór bezpieczeństwa, L1: króciec pod manometr, L2: króciec pod wyłącznik ciśnieniowy, M1: właz rewizyjny

PODSTAWOWE WYMIARY ZBIORNIKÓW SPRĘŻONEGO POWIETRZA

| Type |

Nominal diameter DN [mm] |

Capacity V [Litr] |

Total height H [mm] |

Jacket's height h [mm] |

Distance from the base to lower bottom head h1 [mm] |

Distance between connectors "N1" and "N2" L [mm] |

Connectors' diameter dn [mm] |

Safety valve connectors' diameter dn1 [mm] |

Bottom outlet connector G [cal] |

Mass [kg] |

| ZSP2 | 800 | 850 | 2215 | 1350 | 300 | 850 | 50 | 25 | 1 | 268 |

| ZSP3 | 800 | 1060 | 2617 | 1750 | 300 | 1375 | 50 | 25 | 1 | 352 |

| ZSP4 | 1000 | 1506 | 2517 | 1500 | 350 | 1000 | 65 | 25 | 1 | 428 |

| ZSP5 | 1000 | 1700 | 2767 | 1750 | 350 | 1375 | 65 | 25 | 1 | 466 |

| ZSP6 | 1200 | 2015 | 2471 | 1300 | 400 | 800 | 80 | 32 | 1 | 625 |

| ZSP7 | 1200 | 2525 | 2921 | 1750 | 400 | 1375 | 80 | 32 | 1 | 734 |

| ZSP8 | 1400 | 4075 | 3371 | 2100 | 400 | 1600 | 100 | 40 | 1 | 995 |

| ZSP9 | 1600 | 6060 | 3771 | 2400 | 400 | 1900 | 100 | 40 | 1 | 1460 |

| ZSP10 | 1800 | 6185 | 3217 | 1750 | 400 | 1375 | 100 | 40 | 1 | 1515 |

| ZSP11 | 1800 | 10640 | 4975 | 3500 | 400 | 3000 | 100 | 40 | 1 | 2325 |

| UWAGA: Zbiorniki sprężonego powietrza o większych pojemnościach wykonujemy na indywidualne zamówienie. Dla podanych wymiarów przyjmuje się tolerancje zgodne z obowiązującymi przepisami. | ||||||||||

USE

Compressed air tanks are used for storage and providing appropriate (stable) pressure in compressed air systems. Compressed air tanks type ZSP can be exploited at max permissible pressure PS=10bar and min/max permissible temperature TSmin=0°C / TSmax=+80°C.

COMPRESSED AIR TANK CONSTRUCTION

All the basic elements of compressed air tank (jacket, elipsoidal bottom heads, manholes, connectors, etc) are made of certified carbon steel. Permissible pressure PS cannot be exceeded while exploiting the tank. The construction allows to run the full internal revision through the oval or eliptic revisory hole.

Compressed air tankl is protected against to corrosion by painting: internally – paint with PZH certificate, externally - universal temporal protective paint. Manufacturer allows using other internal varnish sets (eg. epoxy resins) and executions with external surface painting (eg. set of polyurethan paints) - for client's special wishes.

Manufacturer can also offer devices with other anticorrosion protections eg. by:

hot galvanizing, two-sided

spray galvanizing

We also offer compressed air tanks made of austenitic steel.

The manufacturer allows also some constructional changes of the vessel in the range of connection sockets' placing and diameters.

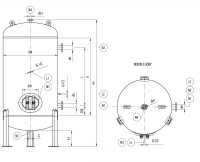

PRZYKŁADOWY SCHEMAT PODŁĄCZENIA ZBIORNIKA SPRĘŻONEGO POWIETRZA

NOTE!

- Compressed air tanks ZSP are subjected to the instruction 87/404/EWG (type ZSP1, ZSP2) and 97/23/WE (PED) (type from ZSP3 to ZSP10) and because of this they are CE signed.

- For compressed air tanks ZSP3-ZSP10 we have the research type B1 in accordance with the instruction 97/23/WE approved by the UDT-CERT Unit Nr 1433, certificate nr 3292/JN/2005/002/06.

- For ZSP tanks we have the PZH certificate which allows contact with drinking water.